- Home

- Products

- MasterShield

- Chemical Resistant Liner & Coating

- MasterShield AKS KNB

MasterShield

MasterShield AKS KNB

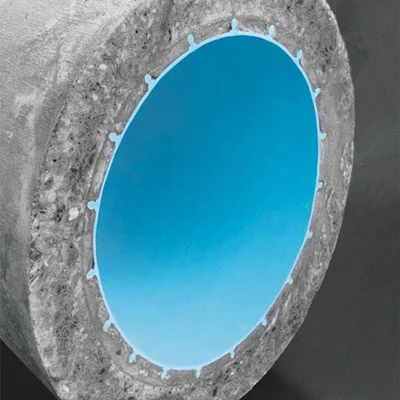

HDPE Concrete Protection Membrane

How Does MasterShield AKS KNB Work?

MasterShield AKS KNB is a high-performance synthetic membrane composed of HDPE sheet with integrally moulded anchors, designed to be cast into concrete to create a flexible and durable corrosion protection lining.

MasterShield AKS KNB is supplied and installed as a fully sealed, welded system that offers robust chemical resistance. The system includes proprietary detailing for sealing around service penetrations and against non-HDPE substrates.

MasterShield AKS KNB can be integrated into new concrete structures or retrofitted onto existing surfaces using compatible MasterFlux grouts. With a proven track record in highly aggressive environments, MasterShield AKS KNB-lined structures have demonstrated a design life exceeding 100 years in the most demanding applications.

MasterShield AKS KNB is used to protect concrete surfaces in chemically aggressive environments in sewerage tunnels, treatment works, pump stations, manholes and chemical retention bunds.

It comes in a range of colours and thicknesses and can be applied to new and existing structures for protection or enhancement.

What Are the Benefits of MasterShield AKS KNB?

Fully welded homogenous lining - all seams and joins are extrusion welded and tested by spark or vacuum box testing.

Chemical resistance - exceptional resistance to aggressive chemicals, making it ideal for environments with exposure to acids, alkalis, and industrial.

Long-term durability - designed for a 100-year service life with minimal maintenance requirements, reducing lifecycle costs.

Versatile application range - suitable for varying temperatures and installation methods, including extrusion welding and grouting.